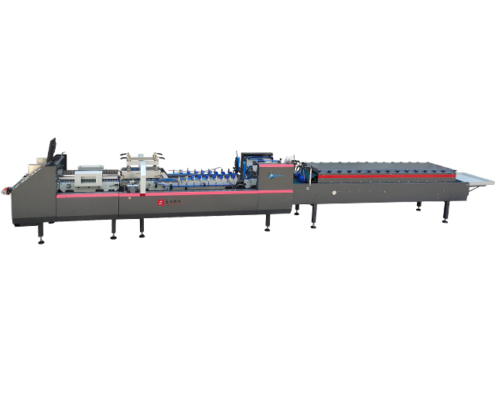

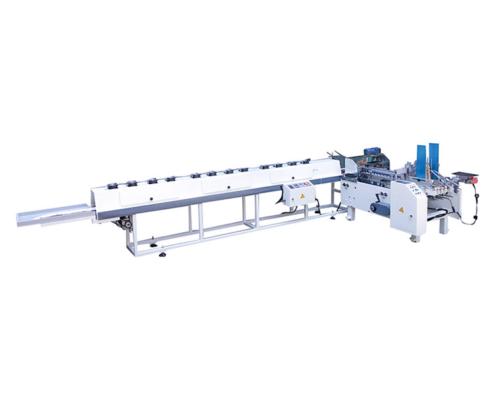

In the packaging and printing industry, the application of folder gluer machine is the last step of packaging box processing. Work efficiency is improved and labor cost is lowered because of appearance of folder gluer machine.

According to the setting of the paper feed knife row, the paper feeding section ensures that only one sheet of printed and die-cut paper is fed every time. The machine uses the principle of synchronous belt or chain transmission to transport the paper to the back part.

In the subsequent part, different models have different functions, such as pre-folding function, bottom hook function, gluing function, etc. Take the single-sided paper box as an example. The middle section of folder gluer machine is equipped with a glue box, and then the paper box is folded according to the indentation line using a belt and a supporting wheel.

Box gluers are mainly divided into the following categories: single-sided box gluers, pre-folded box gluers, hook bottom box gluers, four/six corner box gluers, and special-shaped box gluers. The same machine is suitable for a certain range of carton sizes.

Normal operation and daily maintenance can extend the service life of the folder gluer. List some maintenance knowledge as follows.

After each use, clean the glue box; Before finishing work, check whether there is glue on the belt. If there is glue, clean it in time; It is strictly forbidden to adjust the speed when the governor is stopped, otherwise the belt wear will be very serious.

In conclusion, with the birth of folder gluer machine, the packaging technology industry has developed rapidly. Machine production replaces manual production, reduces labor costs, improves production efficiency, and its development prospects are unlimited.