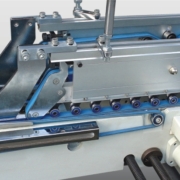

Belts of box folder gluer machine

It is inevitable that the belt will be misaligned during the process of gluing. So how to solve the problem of belt misalignment during work?

I. deviation and its handling. There are many reasons for the deviation of the belt conveyor, the first of which is the low installation accuracy and poor daily maintenance.

During the installation of the conveyor, the head and tail rollers and the intermediate rollers are always kept on the same centerline and parallel to each other to ensure no deviation or less deviation. In addition, the strap joint should be correct, and the multiple circumferences should be the same. If deviation occurs, check the following factors and determine the cause for adjustment. The frequently checked parts and treatment methods for deviations are:

1.Check the deviation value of the two planes of the bearing seat of the head and tail frame. If the deviation of the two planes is greater than 1mm, the two planes should be adjusted in the same plane. The adjustment method of the head roller is as follows: if it runs off the right side of the roller, the bearing seat on the right side of the roller should move forward or the bearing seat on the left side should move backward. If you run off to the left of the drum, the bearing seat on the left side of the drum should move forward or the bearing seat on the right side should move backward. The adjustment method of the tail roller is just the opposite of that of the head roller.

2.Check the position of the material on the conveyor belt. If the material is not centered on the cross section, it will cause deviation. If the material deviates to the right, the belt deviates to the left, and vice versa. The material should be centered as much as possible during use. In order to reduce or avoid this kind of deviation, a baffle plate can be added to change the direction and position of the material.

3.Check the misalignment between the horizontal centerline of the roller and the longitudinal centerline of the conveyor belt. If the non-coincidence value exceeds 3mm, the long mounting holes on both sides of the roller set should be used to adjust it. The specific method is to deviate to which side, which side of the roller set moves forward in the forward direction, or the other side moves backward.

II. Belt slip of the color box gluing machine and its solution. In operation, there are many reasons for slipping. Common causes and solutions are:

1.The friction between the drive roller and the belt is not enough to cause slipping. The reason for not wanting is mostly water or humidity. The solution is to add some rosin powder on the drum. But be careful not to add it by hand, but use blast equipment to blow in to avoid accidents.

2.Too fast starting speed can also cause slippage. You can start slowly at this time. If a squirrel cage motor is used, it can be started after two jogs, which can also effectively overcome the slipping phenomenon.

3.The initial tension is too small. The tension leaving the drum is not enough to cause slippage. This kind of situation usually occurs at startup. The solution is to adjust the tensioning device to increase the initial tension.

4.If the load is too large, it will slip if the motor capacity is exceeded. The advantage of slip at this time is to protect the motor. Otherwise, the motor will be burnt after a long time. But for operation, it is a slip accident.

5.The tail roller bearing is damaged and does not rotate or the upper and lower roller bearings are damaged too much. The cause of the damage is that the tail floats too much, and the damaged or inflexible parts are not repaired and replaced in time, which increases the resistance and causes skidding.

The belt of the color box gluing machine should also undergo necessary maintenance, otherwise it will directly affect the effect and progress of the gluing box, so pay attention to it.

Leave a Reply

Want to join the discussion?Feel free to contribute!