What is a folder gluer machine?

The world’s first folding gluing machine was produced in 1903. Before that, pasting cartons was done by hand. This work was time-consuming and laborious, and it was a long process. The box pasting machine is to fold and paste the paper after die-cutting. Compared with early mechanical equipment, modern mechanical equipment has the same working principle, but better precision and faster speed.

What material can be used in folder-gluers machine?

First, put the flat paper on the paper feeding part and the head of the box folding gluing machine. With the operation of the machine, the paper comes to the gluing part, folding part and pressing part in turn. In the folding part, the machine will fold according to the indentation line on the paper. The box processed by the folder gluer machine is supported by hand, and the box changes from plane to three-dimensional. The paper of many materials can be applied to the box folder gluer machine, such as the following materials:

Carton paper

PVC/PEP paper

Laminated oil paper

Corrugated paper

The box pasting machine is used in many industries, but it is mainly used in the production and packaging industry. The equipment is a highly specialized machine, and its operation process is very accurate. The box pasting machine is used to produce different types of boxes and boxes, including lock bottom boxes, linear boxes, multilateral boxes, etc. For different box types, the production capacity is 50k-200k per hour. The following are the steps involved in this process.

- After the paper is printed, enter the die-cutting machine to cut the indentation.

- Put the die-cut paper on the box pasting machine and move the paper to the correct position through a series of conveyor belts, pressing wheels, guide rails and other auxiliary tools.

- As the paper moves, the machine glues the carton and folds the paper in the folding part.

- The folded paper comes to the pressing box part to make it press more firmly.

- Workers wait at the tail of the machine and pack the pressed boxes.

The machine will perform different operations according to different box types. Folding gluing machine can be used with a waste kicker. Kick the waste opportunity to mark the box that does not meet the standard and kick it out of the assembly line. In addition, the folder-gluer can also be used with an encoder. The system records the production process of each box so that there is a trace to follow.

Parts of a folding gluing machine

-

Feeding part

Feeder is an important position of a folder gluer machine. Boxes don’t go preciously if it’s not correct in the feeder. Technician needs to make sure that the paper is positive when it comes out.

-

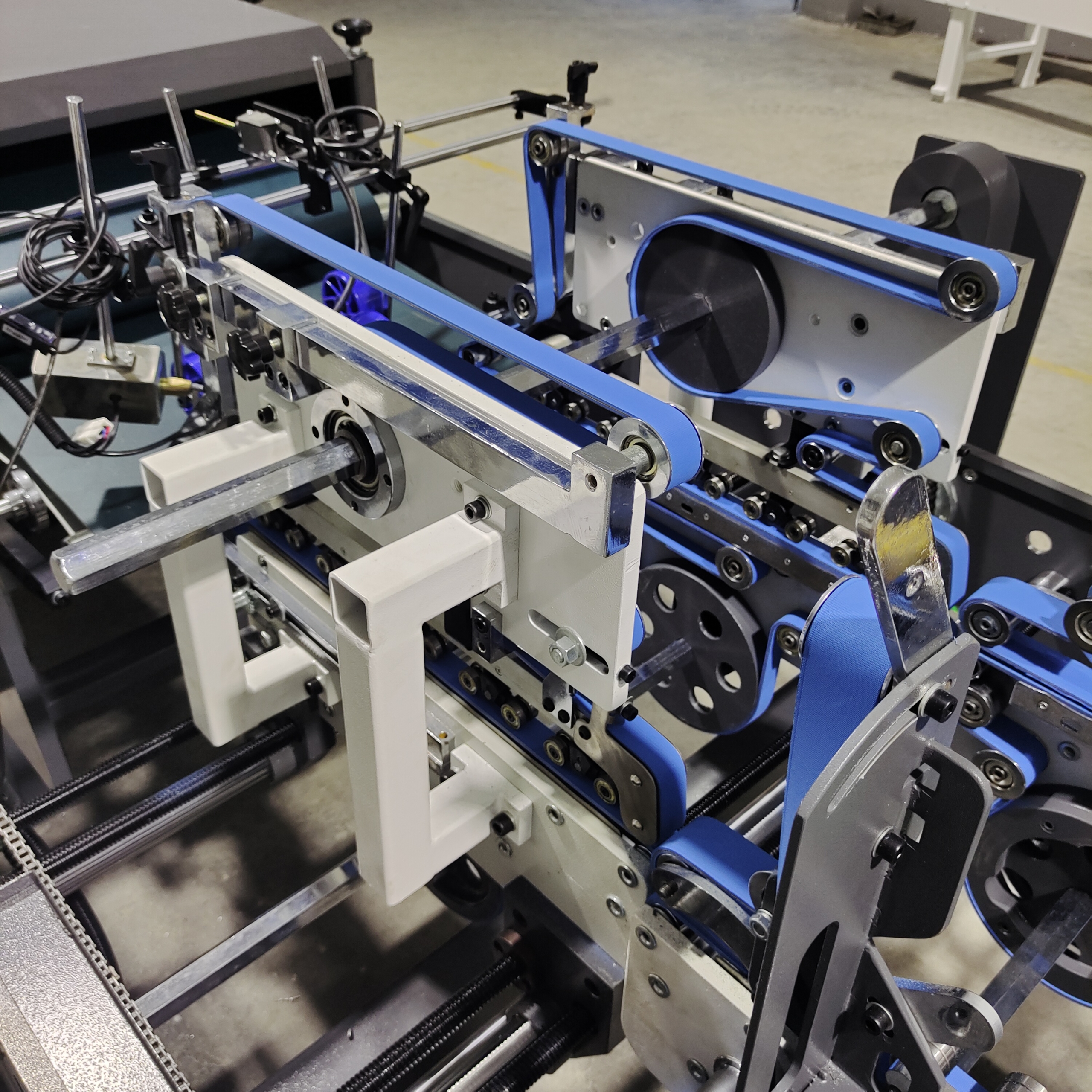

Pre-folding section

There are 2 spare parts in pre-folding position. The right one can pre-fold box by 135 degree and the left one by 180 degree. The aim of pre-fold is to help boxes work with package machine of putting goods into.

-

Lock bottom module

The bottom of the hook is a very important part of the machine. The main function of this part is to produce boxes with hook bottom. It uses four high-precision hooks to fold the ears at the bottom of the box

-

Folding section

Folding part completes final folding job by belts.

-

Conveyor

The pressing part is the last part of a folder-gluer. Its pressure is adjustable to ensure strong adhesion where the glue was applied.

A range of other parts can be installed on a folder-gluer. These parts are used for more customized projects and may include some of the following.

- Loaders

- Packers and banding machine

- palletizers

- Specialty feeders

What should be paid attention for When Purchasing a Folder-Gluer?

Whether individuals or enterprises, it’s a high expenditure of purchasing equipment. Therefore, when choosing the folder gluer machine, people should understand which functional equipment meets their needs. Whether the company purchases new machines or updates existing machines, they should refer to the following aspects before purchasing.

-

Check the workmanship of the machine

When buying a box gluer machine, the craftsmanship of the machine is the first standard to be considered. Most companies buy this type of machine to do a lot of work. If the process level is not up to standard, the machine will not be able to complete the project with high precision, and there may be frequent failures.

The frame structure of the machine is also one of the criteria for selecting the machine. The thicker the frame, the better the stability of the machine and the more stable the operation. In addition, you also need to look at the height of the machine. The lower the site, the more stable the machine will be. The smaller the vibration generated during operation, the more accurate the final product will be,

It should be noted that box pasting machines with castings and angle iron should not be purchased, because this structural type of box pasting machine may produce strong vibration during operation. With the increase of machine age, the accessories on the machine will become loose, resulting in guide pillar failure.

-

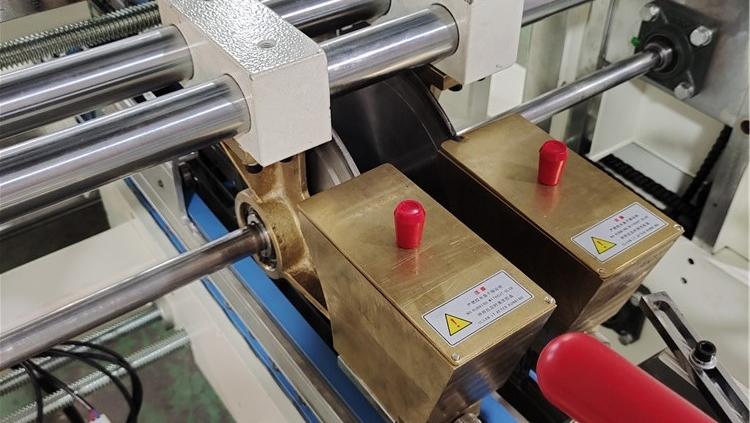

Check the security of the machine

There are many movable parts on the box pasting machine, which may cause harm if they fall off accidentally. When most box pasting machines in the market are produced by manufacturers, they are equipped with safety protection mechanism to increase the safety of users. However, it is recommended to check the following items before purchasing the machine.

- Check that the machine is equipped with a safety cover

- Is there an emergency stop switch at the tail

- Whether there is a travel switch in the middle of the machine to monitor the box moving at any time. In case of abnormality, the travel switch will transmit a signal to the main control room to stop the equipment automatically.

- Is there a roar warning when the worker starts up

These are some of the safety functions that any box pasting machine must have. If you are considering or the existing machine does not meet the above standards, please contact the manufacturer to add these protective measures.

Material paper can be run on the machine

The materials that can run on the machine are cardboard and corrugated paper. Before purchasing the machine, you should carefully check which materials can be applied to the machine. Focus on the following aspects.

- Check if it can work with carton paper 210-800gsm.

- Check if corrugated box, even 5fly, can be done with the machine.

- Check if it has a grinder to polish UV coating surface.

- Check if the spare parts scratch the printed surface.

Although it is a small investment, we should also understand the function, structure and practicability of the machine. The more you know about the machine, the more you can choose the machine you need.

Normal functions on folder-gluer machine

The box pasting machine on the market has thousands of functions, but they are inseparable from the two most basic functions.

-

Side paste function

This is a function of folding the unfolded carton left and right that is, folding the second line and the fourth line. The industry calls this type of side gluing box. This type of box is widely used in the packaging of medicine boxes, cosmetics boxes, stationery boxes and other industries. For the side pasted boxes, the capacity of the machine is 50000 pieces per hour. This kind of box has the advantages of simple structure, convenient folding and strong practicability. Therefore, it is widely used in the municipal packaging field.

-

Crash lock bottom function

The bottom hook function is one of the most common functions in the box folder-gluer machine. Europeans and Americans like to call it a 3-point gluing machine. As the name suggests, the machine glues the three parts of the carton and completes the folding action. The bottom hook box shall be used for boxes loaded with heavy items, such as mask box, syrup box, toy box, etc. The machine needs more action to complete the bottom box. Therefore, the crash lock bottom machine is longer than the side gluing machine. The size of the equipment also needs to be considered when purchasing the machine. The equipment shall be purchased rationally in combination with their own site.

-

Pre-fold function

Pre folding function is a very practical function. The pre folded box can work with the cartooning machine. The efficiency of the production line is greatly improved and the expenditure of labor cost is reduced. The common pre folding methods are 180 degrees for the first line and 135 degrees for the third line. The pre folded box can be opened very easily. Even if the cartooning machine is not used later, this function can also improve the speed of manual cartooning.

-

CD function

The name of CD function comes from the box made by this function, which is often used to hold CDs. With the development of science and technology, CD is gradually eliminated by the market. But the name was retained. Now, the CD function can be used to produce boxes similar to CD boxes, such as SIM card boxes, windows CD boxes, etc. CD function can be used in combination with side pasting machine or bottom hook machine. The buyer shall purchase the box folding gluing machine according to the box type.

-

Other functions

Factory can customize folder-gluer according to customer requests. Usually, it’s to do special hard project. Many kind processors like to produce heterosexual boxes because they are profitable. Although the cost of purchasing equipment is high, its cost recovery is also fast. If there is a list, you can return the capital in more than half a year. One set of equipment can be used for more than ten years, and the profit can be imagined.

After sales service

To maintain a long-term trade relationship, after-sales is very critical. Folder-gluer machine manufacturer should provide perfect after-sales service for each purchase user. When the machine arrives at the buyer’s factory, the box pasting machine manufacturer shall send technicians to install, debug and train. Users need to prepare enough cartons for technicians to test the machine and training guidance.

It is also the unsinkable responsibility of users to actively learn the startup technology of box pasting machine. Scientific start-up method can avoid unnecessary applause, prolong the service life of the machine, improve the production capacity of the equipment and maximize the benefits. Daily cleaning and regular maintenance are also very important. After the daily work is completed, the rubber box, rubber wheel and belt shall be cleaned in time. This can increase the service time of the machine and improve the input-output ratio. Before purchasing the machine, you should understand the warranty period and scope of the equipment. In addition, ask the manufacturer for the list of vulnerable parts for use when replacing parts in the future.

Providing 24-hour lifelong after-sales service is the responsibility of every business. It is the duty of every citizen to promote the orderly development of the commodity market.

Conclusion

The box pasting machine has a development history of hundreds of years. With the development of science and technology, mechanical equipment is constantly updated and improved. At present, the packaging industry is becoming more and more mature. It is a qualitative leap from the initial demand to the current focus on quality. Now there are a variety of box pasting machine suppliers with uneven quality in the market. I hope this article can provide you with purchase standards and ideas and make the choice that best meets your own needs.

It’s nice that you talked about how a print folder gluer is a highly specialized machine, and its operation process is very accurate. I was watching an education program about a factory tour yesterday and I saw the use of folder gluer there. It seems to be quite a fascinating and convenient machine and I could definitely understand why it is being used nowadays.

Greetings! Very useful advice within this article! It is the little changes that produce the most significant changes. Thanks for sharing!

it explains the machine clearly